EZ1 & EZ2 Liner

Inversion Products

Invert with air, water, or both!

EZ1 For Water Only | EZ2 For Air and Water

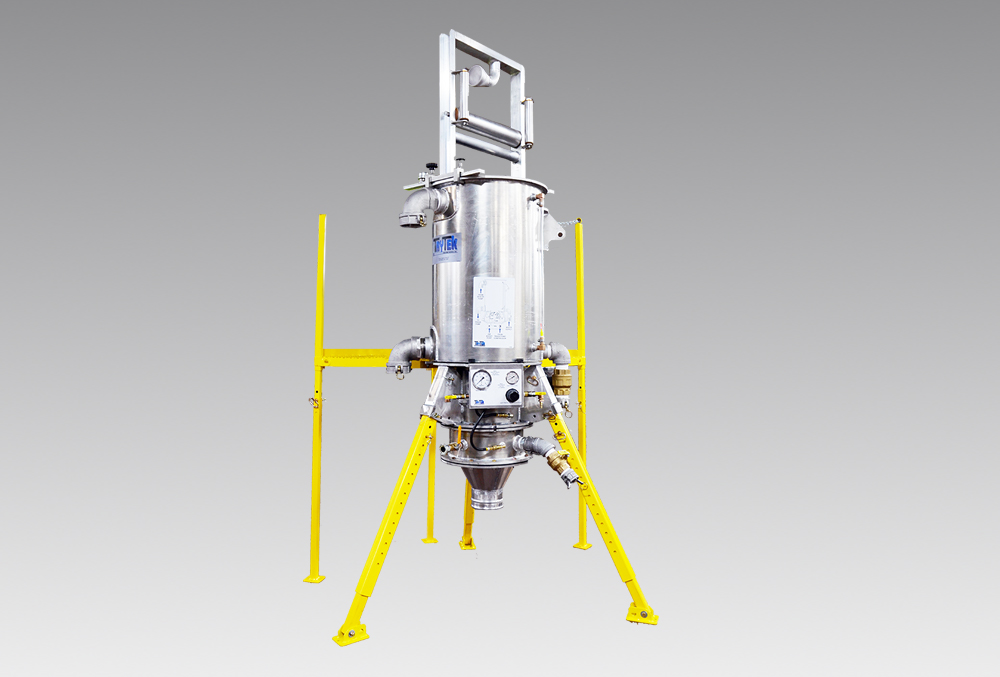

EZ1 & EZ2 Liner Inversion Products

The EZ1/EZ2 Inversion Units uses water or air pressure, depending on the model, for inversion without the need of high scaffolds or lift trucks. The EZ1 model inverts with water only and the EZ2 model inverts with air or water. When using water, the EZ Series utilizes public water available from hydrants. A hot water boiler is then used to cure the liner. Gauges on the EZ Series are used to monitor and control the pressure(s) throughout the inverting and curing process.

Features

- Inverts lengths over 1,000 ft. with water

- Cures with water or steam

- Invert with air, water, or both

- Low profile, no need for high scaffolds or lift trucks

- Utilizes public water from hydrants

- Monitor and control the inverting and curing process

- Inverts CIPP liner from 4″ (150 mm) to 18″ (460 mm)

- Bolt-On-Boots for 6″, 8″, 10″, 12″, 15″, and 18″

- Optional: 4 Inch Bolt-On-Boot & Liner Lubrication System

- Round pressure chamber

- Roller and Capstan – assist in controlling tube insertion

- Platform scaffolding included

Product Resources

Brochures

This brochure that will go over everything you need to know about the EZ1 & EZ2 Liner Inversion Products. This brochure can be downloaded and/or printed out.

Videos

See one of TRY TEK’s Inversion Units in action!

Watch Video

Watch the unpacking and assembly of a CWP Inversion Unit.

Watch Video

Learn how to replace the bladder on your unit.

Watch Video