Trenchless Sewer

Pipe Rehabilitation

An Industry Overview

Where TRY TEK Equipment is Used

When people think about broken underground pipes, they think about the liquid or gas in the pipe leaking out into the environment, causing a major hazard or wasting of resources. While this is true for gas or water pipes, the biggest problem for broken sewer lines is that ground water infiltrating into the sewer pipe, which is known as “Inflow and Infiltration” (INI). Sewer pipes can develop cracks and joints can separate due to ground shifts from floods, earthquakes, traffic, and changing groundwater levels. This causes a problem at the sewage processing facility. Now, not only does the facility have to process normal sewage, but also the groundwater that found its way into the cracks in the pipe. The amount of water being unnecessarily treated can be very substantial, especially during heavy or extended rains. This can cause a need for unnecessary and expensive expansion of facilities. Not only is INI costly for the sewage treatment plant, it can cause dangerous erosion. As the groundwater flows into the pipe it carries with it small particles of soil, slowly eroding areas around the pipe and possibly causing dangerous sinkholes at the surface level. The traditional method for addressing this type of problem was to dig up the old pipe and replace it.

Trenchless Sewer Pipe Rehabilitation History

Trenchless sewer pipe rehabilitation for non-man-entry pipes began as far back as the 1920s with the use of the “Cement Mortar Lining” process for water pipes. By the 1950s grouting systems were developed for the sewer pipe industry. This is a tedious process and does not restore the structural integrity of the pipe. Plus, new cracks can develop in the same pipe that was just grouted. In 1971 a process was developed in England to repair sewer pipe without digging. By inserting a soft liner that can then harden, into the broken sewer pipe a new pipe could be placed inside the old pipe, with all the work done from the manholes. The new pipe liner covers over all the cracks from manhole to manhole, sealing tightly against the original pipe. Structural integrity is restored and flow is improved because the pipe surface is much smoother. Above ground there are no piles of excavated dirt, minimal traffic tie-ups, no risks of disturbing other nearby buried utilities and no complaints about disruption.

Cured-In-Place-Pipe (CIPP)

The technology has become known as Cured-In-Place-Pipe (CIPP) and has been a successful forerunner in the trenchless pipe-rehabilitation industry. Thousands of miles of pipe have been relined throughout the world for everything between 3” to over 100” diameters. Use of CIPP is now becoming commonplace, and is no longer just for special applications where excavation disruption or costs are too prohibitive.

Millions of feet of CIPP materials have been installed worldwide, have withstood every corrosive environment, and has survived the test of time. Billions of dollars have been saved because excavation was eliminated. From England the technology has expanded all over the world, the largest market being in North America. This same technology is also being used to repair natural gas and water pipelines.

The Process of Relining & The Essential Equipment Needed

Pipe Inspection

The Cured-in-Place-Pipe (CIPP) process for a sewer mainline begins with a pre-inspection of the pipe to determine if the pipe needs repaired. At the same time any obstructions will be noted for removal prior to relining. Active laterals that need to be preserved are determined plus, accurate measurements on pipe length, diameter and the precise location and radial position of laterals are recorded. Mobile inspection systems have the ability to measure distance of travel inside the pipe. The laterals radial positions are also noted. From this critical information the laterals can be located after they are covered over by the liner material. The data collected is then brought back to the contractor’s facility where pipe design calculations are performed with special software. This critical data is required to design a CIPP liner that, when installed, will meet the required standards.

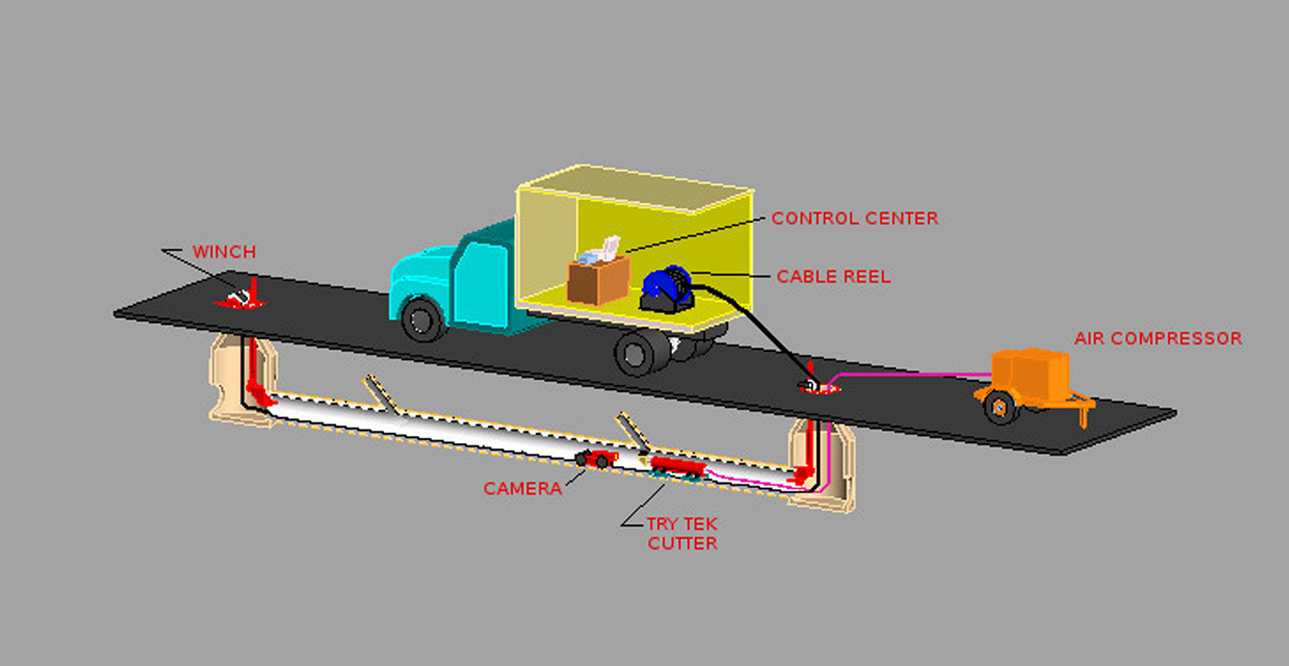

Pre-inspection is done using a mobile inspection system. A mobile inspection system consists of a self-propelled pan & tilt camera, an electrical cable, cable reel, and the command center. The electrical cable and cable reel power the camera and transmit data back and forth between the camera and command center. The electrical cable may be a multi-conductor cable or a single conductor cable, depending on the manufacturer’s design. The command center may be as basic as a cable reel on a cart with video controls and a monitor. Or it may be a dedicated vehicle like a box truck, trailer or van containing a desk, computer, video equipment, cable reel, winch, and workbench.

Pipe Cleaning

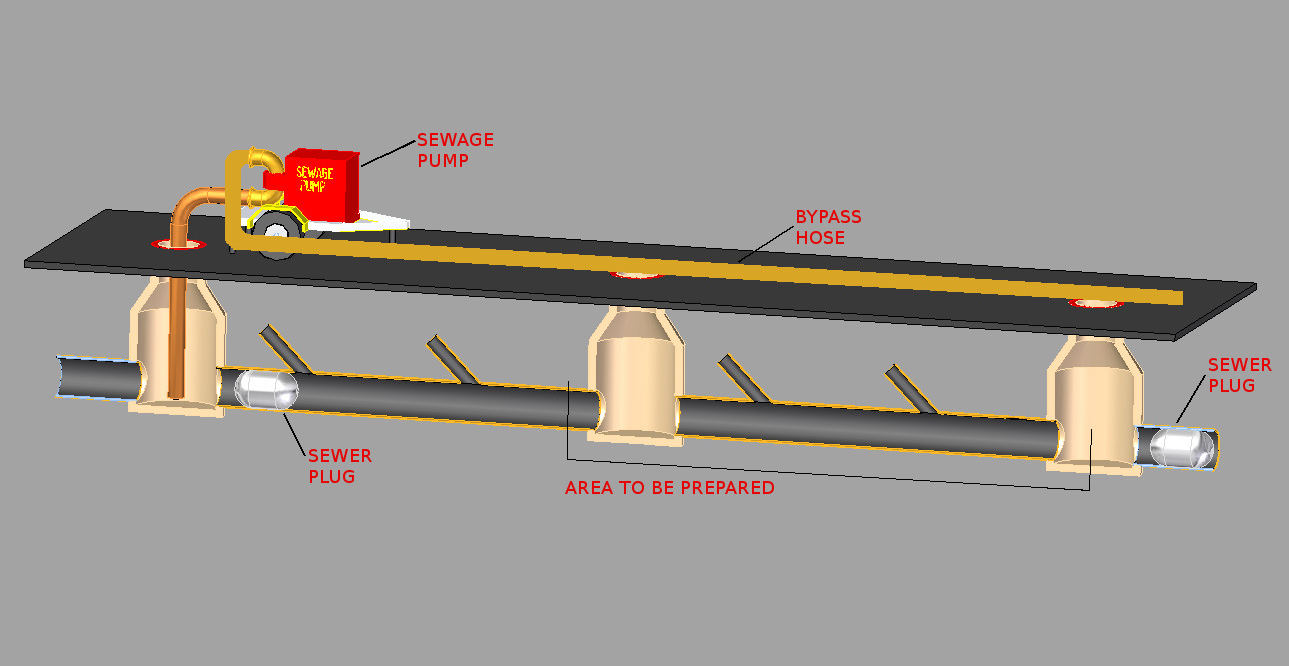

After analyzing the data, the materials and equipment required are scheduled for the day the work is to be done. When the work is begun, the section of pipe to be lined is isolated with an upstream pipe plug. A sewage pump removes the sewage from the upstream manhole, bypassing the section of pipe to be repaired and into another manhole downstream. This is called bypass or over pumping. Special bypass pumps, hoses and plugs are required for this process. Pumping is not required for gas and water; only bypass piping.

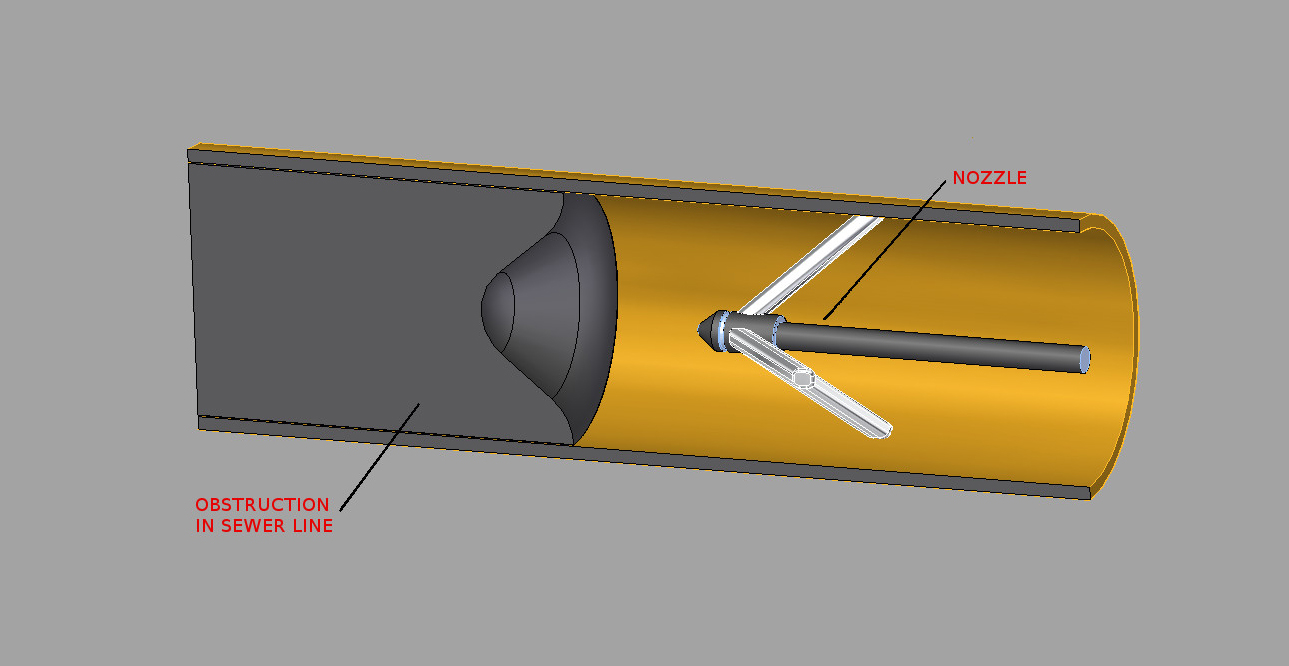

Now that the pipe section is isolated from the upstream flow, the pipe can be cleaned using a jetter. This requires a nozzle designed and sized for this application, a high-pressure hose, and a jetter pump located above ground. There are various types of high-pressure water jetter systems available that will allow you to clean debris as soft as mud to as hard as concrete. This process brings the heavy debris from the higher manhole to the lower manhole, where it is either jetted further down the line or sucked out of the sewer system using a high-powered vacuum.

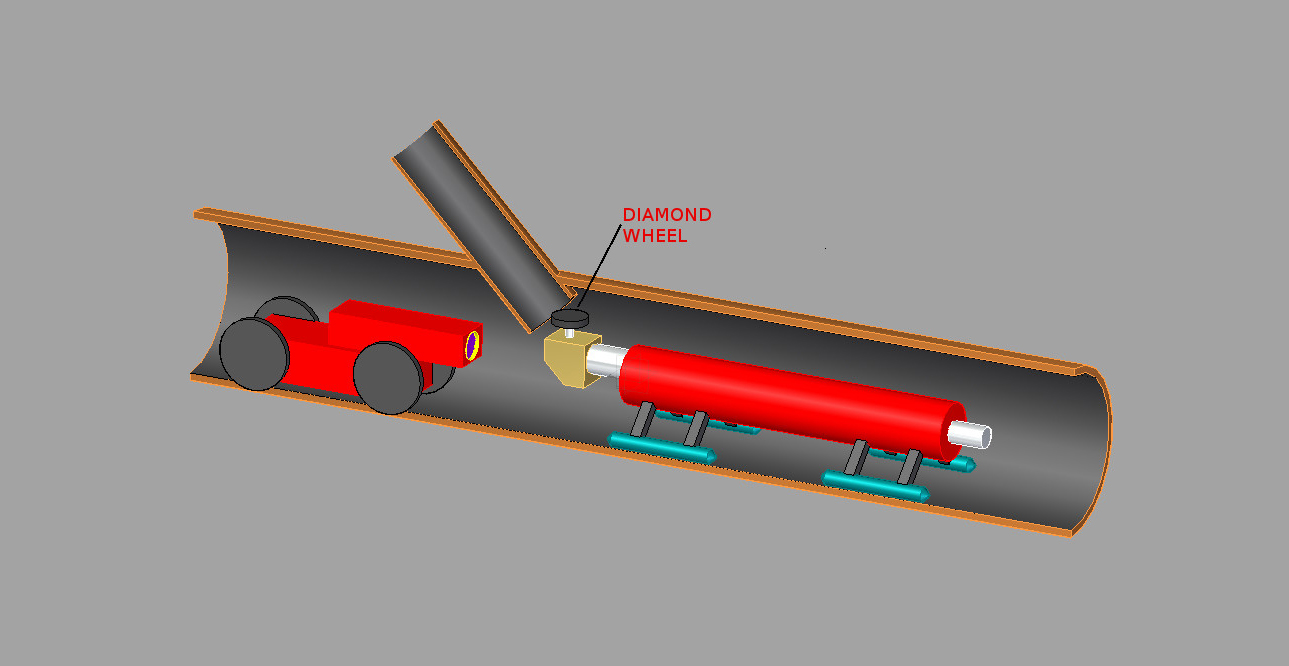

A problem specific to sewage pipe is lateral protrusions which need to be removed. A protrusion is when the lateral pipe extends into the intersecting mainline pipe, and mainly occurs in clay, concrete, and occasionally cast iron pipe. This obstruction in the pipe can limit access to the pipe for cleaning and will definitely eliminate the ability to reline. The lateral protrusion is cut off using a high-torque, water-jet-powered auger or it can be removed using the TRY TEK Lateral Tap Cutter with a diamond-cutting wheel. The diamond wheel method is slower but will cause less damage to the lateral. Now that all obstructions are cleared and the pipe is clean, it is now time to reline.

Liner Inversion and Curing

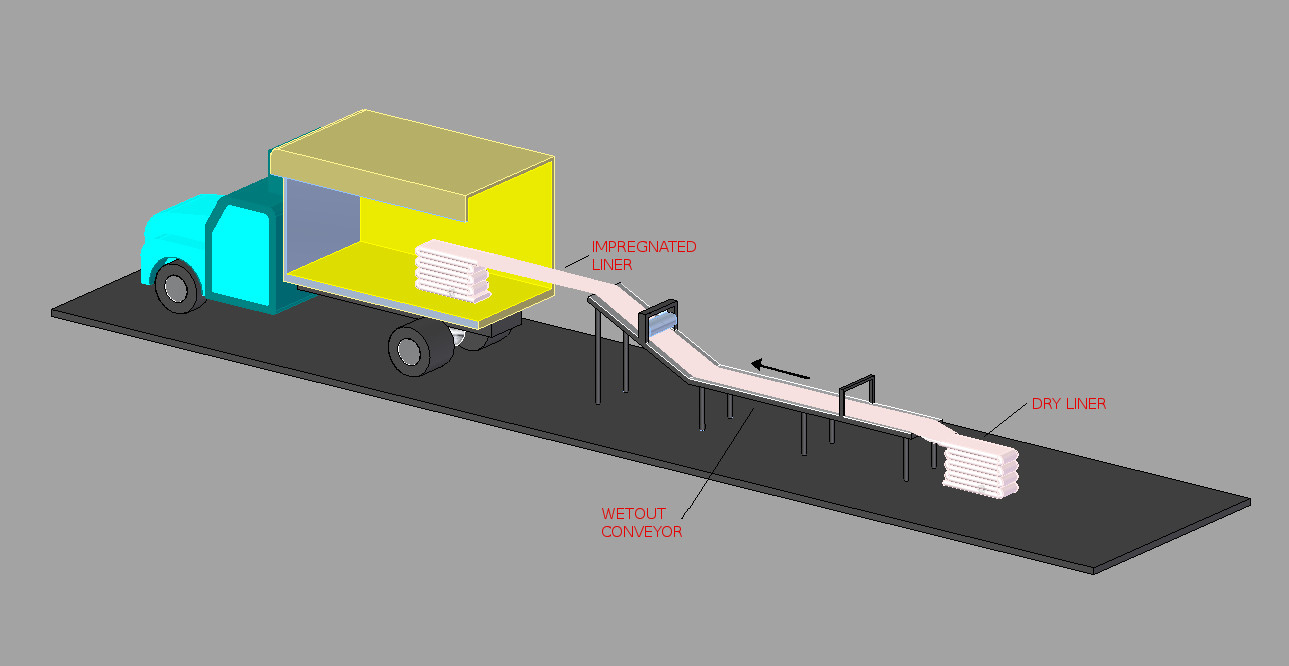

Prior to installing the liner into the pipe the liner needs prepared. This preparation process is called wetting out. Sometimes this process is done onsite, sometimes it’s done at the contractors facility, and sometimes this is sub-contracted to companies that specialize in wetting out. Wet out is the critical process of impregnating a felt tube (the liner) with a calculated amount of catalyzed resin. After wet out, the product is loaded and cooled down for proper shipping to the job site. Heat cured CIPP is transported to the job site using refrigeration trucks. The CIPP Liner is soft and pliable at this point.

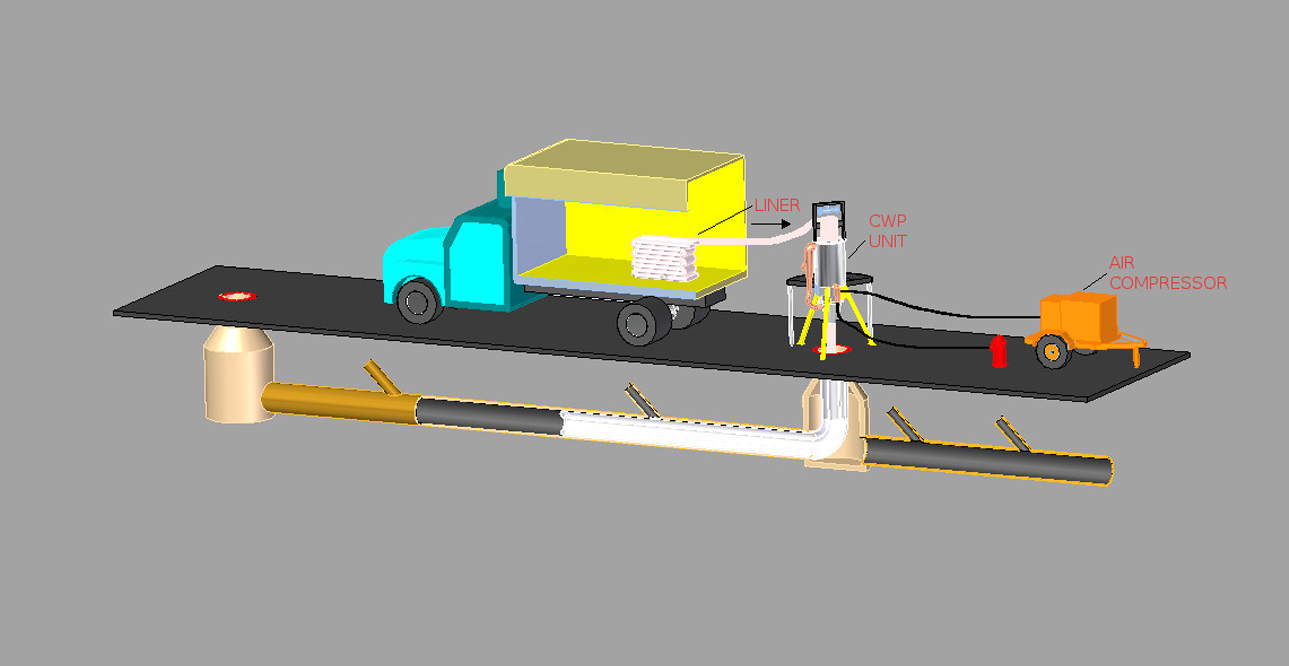

Installation of the CIPP liner can be done using an inversion process or a pull-in-place process. The inversion process is similar to turning a sock inside out. In the inversion process, air or water pressure is used to install the liner. When using the inversion process, special care is taken in using the proper pressures and speed. TRY TEK can provide you with a water inversion unit called a CWP Inversion Unit that will give the control and power necessary to do successful inversions right through the curing process.

Curing the liner is the process of expanding the soft pliable liner against the host pipe and activating the catalyzed resin to make it into a hard pipe with structural integrity. While some catalyzed resins are activated by UV light, most are heat activated and cured with steam or hot water. Careful monitoring of temperatures and pressures are required to assure the liner is properly cured. With proper cool down, there will be a new pipe within the old pipe, with the old pipe no longer being needed for structural support.

The equipment needed for installing and curing liner depends on the process being used. For air inversion system one needs an air compressor, an inversion unit (or shooter), and a steam boiler for curing. For a water inversion system one needs a water source (either a fire hydrant or water truck with pump), a water inversion unit (as shown here) or scaffold, and a hot-water boiler.

Lateral Reinstatement

Now that the liner has been installed, all the connecting laterals (the pipes from house to the mainline pipe) are covered over with the new liner. The new liner needs to be cut open at each active lateral connection. This next step in the process is called lateral or service reinstatement. This task is an art in itself, requiring a lateral tap cutter, a mobile inspection system, an air compressor, winches, various other support equipment and trained personnel. The active services must be accurately reinstated (opened up) and brushed (creating smooth transitions into the new pipe). The operator uses the measurements recorded at the time of pre-inspection to find the active lateral connections. Since there is nothing backing up the liner at these points, the liner will be slightly deformed, creating a concave dimple. This will provide visual verification of the lateral connection as well as help to establish the size and shape of the hole to be cut.

The cutter and camera on sleds are linked together to create a train. This train is pulled through the line with a winch and cable at both manholes. The cutter operator, located inside a truck parked near the manhole, remotely operates the cutter with joystick controls while watching the cutting action on a monitor. The cutter has three axes of movement to allow the operator to cut any shape of hole. In this way, the operator cuts through the liner to completely open (reinstate) the lateral connection. The cutter/camera train is then pulled to the next lateral to be reinstated. When the entire section of laterals have been reinstated, the process is repeated with a wire brush to give a smooth transition between the pipe main and the laterals. Additional sealing at each lateral connection may need to occur.

Finally, after a post inspection is performed to ensure that quality is present throughout the length of the pipe, the CIPP process is completed.